Yannedis & Co Ltd. “Lion” – Troywood ROTOR R3 Bunker

From the surface entrance level to the deepest command floor the bunker has over 100 Internal (single and double-leaf) timber doors; most of which are solid, heavy and fireproof that secure access to a warren of underground rooms and spaces. During the bunker’s 40 years of secret Cold War operations these doors were countlessly opened and closed, locked and unlocked, slammed, kicked, knocked, and pushed – either by personnel of the Royal Air Force (RAF), General Post Office (GPO) or Scottish Office. The specialist nature of bunkers however, required careful consideration over ironmongery so that these doors could withstand the heavy traffic whilst also remaining functional; both during peacetime and in the event of nuclear war. Whether it was RAF crew conducting maintenance on radar equipment, GPO engineers repairing phone lines, or civil servants passing memos between government departments these doors had to be robust, safe, constantly accessible, easily maintained and repaired and also, quiet.

In considering this wear and tear as well as accounting for the bunker’s various programmed functions the original 1950s specification required that certain doors had to stand open and others remain closed (as was necessary in the main corridors for optimising the air conditioning system). To meet these parameters a combination of overhead door closers and floor springs were installed throughout the building. Although a standard specification was applied across all of Britain’s R3 bunkers, the contract for Troy Wood appears to have been primarily awarded to Yannedis & Co Ltd.

As Britain’s “oldest established architectural ironmonger” Yannedis & Co Ltd. (now operating at Lloyd Worrall) was set up in 1911 and supplied a range of standard and bespoke door fixtures and fittings manufactured at its brass foundry located on Theobalds Road in London. Interestingly, as with industry practices today Yannedis also offered free product samples to architects and clients and even dispatched representatives to assist in detailed design specifications and door schedules.

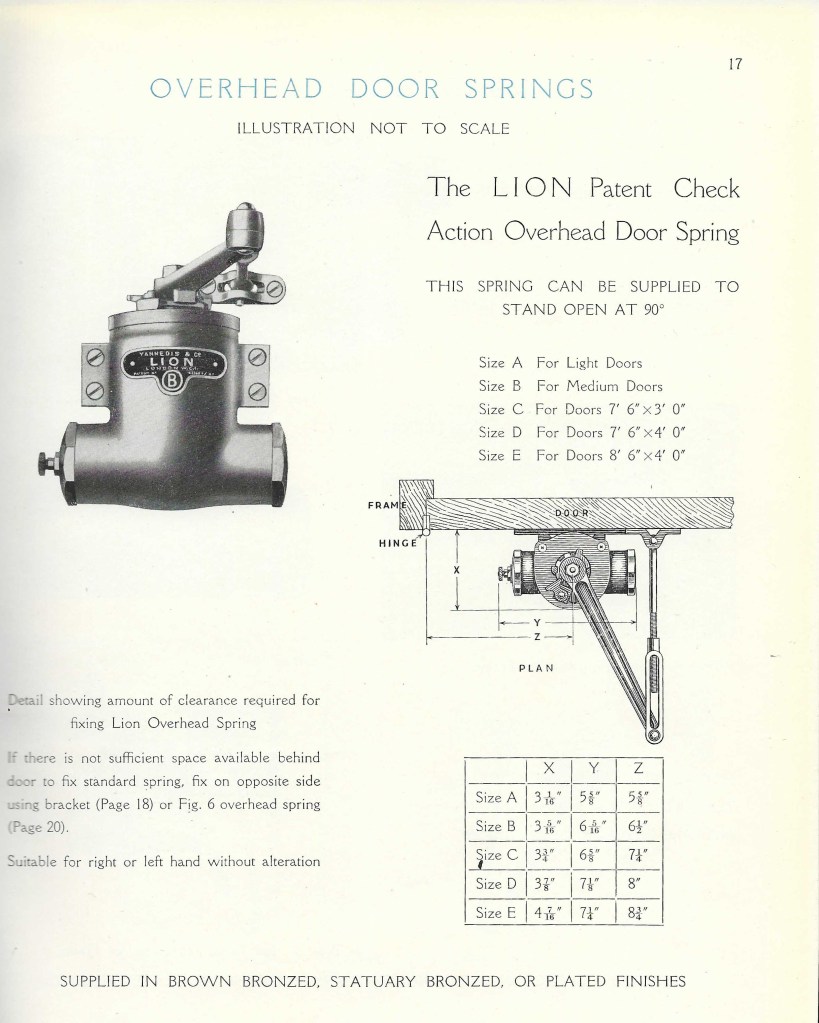

Lion Overhead Door Closers

Described as the “most efficient and trouble-free method of closing doors without noise” the ‘Lion patent check action’ overhead door closer was specified for a number of doorsets. Once fitted the check regulator allowed for simple adjustments without tools as and when required. The Lion overhead door closer was top of the range and Yannedis offered a 5-year guarantee to replace – at no cost – any set that developed manufacturing defects. Importantly, the rear fixing plates are individually stamped with numerical symbols, signalling that each door closer was carefully paired with an assigned door from the architect’s schedule (a marriage to suit the relevant door weights and dimensions). Ultimately this helped the quick and efficient installation of doors that subsequently facilitated the overall completion of the ROTOR programme. This may seem insignificant; however, the bunker would not achieve formal sign off and handover unless its doors were in place. If the doors were not in place, then Britain’s first Cold War air defence system could not be made operational.

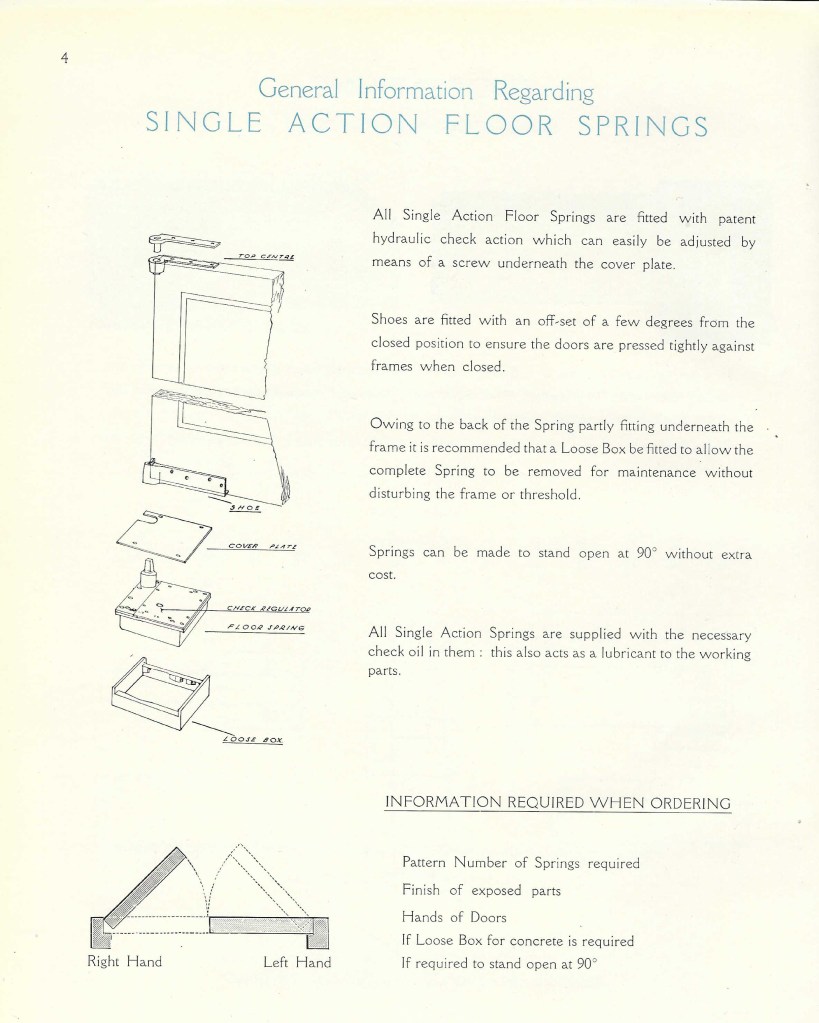

Lion Floor Springs

Most of the doors that were required to stay open were specified with ‘Lion single action floor springs’. A hydraulic check mechanism was fitted within the unit to ensure these doors opened in one direction only, that operational limits (up to a maximum of 90 degrees from its fixed pivot point) were not exceeded and quick alterations could be made with the use of a simple screwdriver. The shoe size however meant the door frame and other necessary partitions often had to be routed to enable the metalwork a flush recess that in turn provide a full closure.

Ease of modification and repair

While these door closers and floor springs were an off-the-shelf product available to civilian markets (widely used in schools and hospitals), their installation, maintenance and repair within the bunker was anything but standard. For in a peacetime context this ironmongery had to be installed, maintained, and repaired by fully vetted contractors who had signed the official secrets act – in order to preserve the bunker’s classified existence. On the other hand, had political tensions boiled over to nuclear war, these bunkers were to be sealed indefinitely: meaning all building repairs had to be conducted with ease and by those already secured within the blast doors. If the unthinkable happened there were no joiners or locksmiths that could be called out to fix these doors in the aftermath of a nuclear strike.

Remaining evidence

Although there have been many alterations throughout the Cold War and beyond where door closers and floor springs have since been refitted with new models the bunker miraculously still features 8 of the original ‘Lion’ door closers; 7 of which are the Lion B type and 1 is the heavier Lion C type. Likewise, 20 Lion floor springs still reside within their original underfloor footings. As a testament to robust post-war British engineering these door closers and floor springs (with their internal coils still oiled) require very little maintenance and function as per their 1950s installation.